The Grow Pros Solutions 8ft Air Circulation Under Canopy Light is designed for delivering light to lower flowers and buds across the grow area, increasing flower density and yield in indoor grow rooms. Mounted beneath the main canopy, it reduces shaded lower tiers so lower canopy buds develop more evenly and finish as denser, more consistent flowers. The aluminum air circulation tube built into the fixture moves air along the row and through the under canopy, bringing airflow without separate duct runs blocking the light or the light body restricting air movement.

| WATTAGE | 250 W |

| SPECTRUM | Full Spectrum + Far Red |

| INPUT VOLTAGE | 120V-277V |

| POWER FACTOR | >0.9 |

| LIFTTIME TESTING | L90: >36,000 hrs |

| THERMAL MANAGEMENT | PASSIVE |

| IP RATING | IP65 |

| WARRANTY | 5 years limited |

| PPE | 3.03 μmol/J |

| PPF | 350 μmol/s |

| WORK TEMP. | 0ºF to 104ºF |

| AMPS @ 120V – 2.08A 208V – 1.20A 240V – 1.04A 277V – 0.90A | Daisy chain option 4 pcs @ 120V 5 pcs @ 208V 6 pcs @ 240V 8 pcs @ 277V |

Grow Pros Solutions Air Circulation Under Canopy Light is built as a combined under canopy light bar and air tube for high-density flowering rooms, using a spectrum developed by Grow Pros Solutions. It delivers optimized lighting to lower flowers while the aluminum ventilation tube moves air through the lower tiers, helping under canopy rows keep pace with the top canopy in both development and finish.

By bringing light and air into the lower plant tiers, it supports stronger flower set, better structure and size, and a more even finish from top to bottom—without adding separate duct runs or extra under canopy hardware that block light or airflow.

In high-density canopy environments, the under canopy tier is where both light levels and air movement drop off first. This system is built to address both at the same time:

Each unit uses a built-in aluminum ventilation tube, making the fixture part of the under canopy air system, not just a light bar. Each fixture connects to the next using a rubber duct connector to create a continuous airflow path along the row.

| CFM | 971.4 |

| Vertical Rack Compatible | Yes |

| Rotating Direction | CCW |

| Rated Voltage | 100–240 VAC |

| Rated Current | 1.5A (Max 2.7A) |

| Rated Input Power | 255W |

| Rated Speed | 3000 ±10% RPM |

| Maximum Airflow | 1652 m³/h |

| Maximum Static Pressure | 1059 Pa |

| Starting Voltage | ≤100 VAC |

| Operating Temperature | -4 ~ 140°F |

| Environmental Humidity | 10% RH @113°F (24h) 98% RH @113°F (24h) |

| Noise Level | 74 dB |

| IP Rating | IP44 |

| Air Sock Diameter | 4 inches (Sold Separately) |

Ensure you do not exceed our recommended maximum daisy-chaining limit when connecting under-canopy lights. Exceeding this limit can lead to performance issues or safety hazards. Please refer to our guidelines for the maximum number of lights allowed per daisy-chain configuration. If you’re unsure, our technical support team is available to assist you.

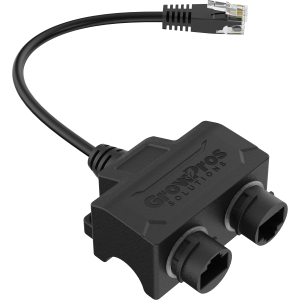

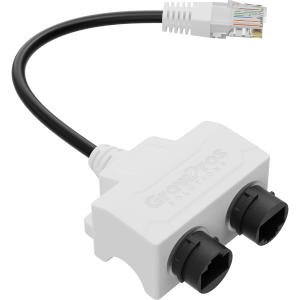

Use our 2-way or 3-way data splitters to control all under-canopy lights with a single controller. These splitters efficiently distribute control signals, simplifying your installation and enhancing system performance. They are designed for seamless integration with your existing lighting setup. For detailed instructions, consult our user manuals or reach out to our support staff.

For more information or any questions about our products and services, please contact us. You can submit a quote form on our website for detailed pricing and product information. Our customer service representatives are available via email, phone, or live chat to provide immediate assistance. We are committed to ensuring your complete satisfaction.

For achieving superior growth results, it's essential to consider the width of your facility's benches and the number of plants you arrange on them. Here’s a concise guide:

Bench Width: If your bench measures 4 feet or narrower, it's advisable not to exceed three plants in width. This setup maximizes space without overcrowding.

Plant Count: Running your facility with a slightly reduced plant count, specifically three plants across instead of four, can enhance plant health and yield.

Lower planting densities facilitate improved airflow around each plant. This increased circulation significantly boosts the productivity of your lower canopy. By managing spacing effectively, you encourage a healthier growing environment that promotes robust plant development.

Adopting these recommendations can lead to improved air circulation and better overall plant performance, helping you achieve optimal horticultural results.

The dimming capabilities of these lights provide you with full authority over the brightness, allowing you to tailor the light intensity to match different stages of plant growth. You can reduce the light output to as low as 35-40% of the maximum intensity, making it adaptable to varying lighting needs.

To achieve this control, the lights are compatible with a variety of industry-standard dimming controllers. These controllers enable seamless adjustment and offer precision, ensuring that your lighting setup can be finely tuned to optimize plant health and productivity.

By utilizing these dimming capabilities along with a compatible controller, you can create an adaptable growing environment that meets the specific requirements at each phase of plant development.

"Spectrum Balancing" is an innovative approach in horticultural lighting that addresses the varying needs of plant cultivation environments, particularly in grow rooms and greenhouses. It focuses on adjusting and optimizing the light spectrum to complement the existing top lighting systems. By fine-tuning these light spectrums and wavelengths, growers can address any deficiencies present in current lighting setups.

Enhancing Product Quality

The key benefit of Spectrum Balancing is the ability to exert greater control over plant development, which leads to higher quality yields. This technique allows cultivators to:

By implementing Spectrum Balancing, cultivators not only increase crop yield but also prioritize the enhancement of product quality, ensuring their produce meets the highest standards.

When planning your lighting setup, it's essential to determine how many power cords and extension cords you'll need. Here's a step-by-step method to get it right:

Identify Your Power Requirements

Each bench or section of your setup will require at least one power cord. However, this can vary based on the number of lights and their total power draw.

Understand Daisy-Chaining

Daisy-chaining allows you to connect multiple lights in series, reducing the number of power cords needed. However, there is a limit to how many lights can be safely daisy-chained:

Apply Scenarios for Better Understanding

By following this method, you can ensure your lighting setup is both efficient and safe. Accurate power management not only helps in reducing costs but also prevents potential electrical hazards.

Waterproof connectors play a vital role in under canopy lighting systems by ensuring durability and safety, particularly in environments exposed to moisture. Here's why they are essential:

Protection Against Moisture: These connectors are designed to withstand water exposure, enabling them to function reliably even in damp conditions. This is crucial for maintaining consistent lighting performance without the risk of short circuits or electrical failures.

Enhanced Safety: With an IP66 rating, waterproof connectors keep electrical connections secure against both water and dust. This level of protection ensures that your lighting setup remains safe, even when integrated with irrigation systems.

Versatility and Scalability: Waterproof connectors allow for the connection of multiple lights using extension cords. This flexibility supports the creation of extensive lighting layouts, adaptable to different architectural needs.

Long-lasting Performance: By preventing the ingress of water and dust, these connectors help extend the lifespan of lighting systems, reducing maintenance costs and enhancing reliability over time.

In summary, waterproof connectors are indispensable for under canopy lighting systems, providing safety, scalability, and enduring performance.

When choosing between Model 1 and Model 2 lights, understanding their differences in spectrum and compatibility is essential for optimizing plant growth.

By choosing the right model for your lighting setup, you can effectively cater to the specific needs of your plants throughout different stages of growth.

Green light can significantly influence plant growth, especially when paired with red and blue grow lights. This trio creates a more comprehensive light spectrum, crucial for optimal plant health.

Incorporating green light with red and blue grow lights enriches the spectrum and ensures that every part of your plant gets the light it needs. This combination not only improves photosynthetic efficiency but also supports robust plant growth from top to bottom.

In most rooms you do not need a separate under-canopy duct run. The aluminum tube is built into the fixture, so the same piece of hardware handles lighting and air movement under the canopy, reducing extra ductwork and hardware that can block light or airflow.

The tube is designed to work with external inline or duct fans. It pairs well with the Quetzalcoatl Air Circulation System from Grow Pros Solutions and can also be used with most standard grow-room inline fans that match the duct size. Fans are sold separately.

Each fixture has a tube end that connects to the next one using a rubber duct connector, so you can run them end-to-end along a bench or rack row. This creates a continuous airflow path while keeping the under-canopy lighting in line with the plants.