A grow glide rack system is one of the simplest ways to increase planting surface without expanding your building footprint. Instead of fixed aisles and static tables, a grow glide rack lets you slide rows together, open a single working aisle where needed, and keep more canopy under each run of LED lighting.

When mobile racking is paired with good light uniformity and clean irrigation layout, floor area starts to work as true cubic-foot production space. The key is understanding how a grow glide rack changes layout, workflow, and lighting design so the room is planned around it from day one.

How Mobile Racking Changes Room Design

From Aisle-First Layouts to Canopy-First Layouts

Traditional layouts are built around fixed aisles: you place benches or tables, then carve out walking space that stays open whether you are working that row or not. With a grow glide rack, the logic flips. You design around canopy first and keep only one active aisle open at a time, gliding rows to access each bay.

This shift dramatically increases the share of the room devoted to productive area. Facilities that move from fixed tables to mobile racking often gain 30–50% more planting surface without changing the building shell. For teams already using rolling benches, it’s a natural step up from layouts like the ones in Next Generation Rolling Bench and Plug 2 Play Rolling Benches.

Stacking Levels to Use Vertical Volume

Once rows can glide, it becomes practical to stack two or three levels of trays above the same footprint. A well-engineered grow glide rack keeps each tier stable, aligned, and reachable, so a single room can be converted from one productive layer into a true vertical system as long as ceiling height and HVAC capacity allow it.

Vertical layouts demand more attention to airflow, dehumidification, and LED placement. Concepts from vertical growing systems and grow table design translate directly into multi-level mobile racks.

5 Smart Advantages of a Grow Glide Rack

1. Higher Production per Square Foot

The clearest benefit of a grow glide rack is more production surface in the same room. Fixed aisles are replaced by moving aisles, so more of the floor can be dedicated to canopy instead of walking space. When tiers are added, that gain multiplies quickly.

This extra canopy makes every LED run more effective. Instead of lighting wide open aisles, more photons land on productive foliage. If you are reviewing fixture choices above mobile racks, the system-level overview in Benefits of LED Grow Lights is a helpful reference.

2. Easier Control of Light Uniformity

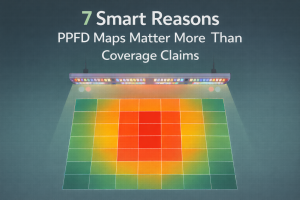

Because each grow glide rack moves as a unit, it is easier to keep the distance between fixtures and canopy consistent. Light bars can be centered above each tray, with repeatable spacing from rack uprights and room walls. That consistency makes PPFD maps smoother and reduces the number of “mystery” hotspots and dark corners.

In dense rooms, especially with multi-level production, lower foliage can still fall into shadow. In those cases, purpose-built under-canopy fixtures—such as the solutions offered at Under Canopy Grow Lighting—can be added to restore balance between upper and lower zones.

3. Smoother Workflow and Better Ergonomics

With a grow glide rack, the room moves to match the work instead of the other way around. Staff open one aisle, complete pruning, scouting, or harvesting along that path, then glide to the next bay. Tools and carts stay in the same lane while the canopy shifts in front of them.

Over time this reduces wasted steps, keeps work zones more organized, and lowers fatigue during peak labor windows. The change is subtle day to day but noticeable when you look at annual labor hours.

4. Cleaner Irrigation and Drainage Layout

Mobile racks encourage standardized plumbing and drainage. Each grow glide rack bay can share the same feed lines, drip layout, and drain collection points. That makes construction more repeatable and troubleshooting easier when the room is live.

When plumbing is aligned with the rack structure, floors stay drier and safer, with fewer trip hazards and puddles under the canopy. Pairing this with durable bench or tray surfaces—similar to the stainless concepts discussed in Hydroponic Cultivation Stainless—helps keep the root zone environment stable over long cycles.

5. Room to Upgrade Lighting and Strategy Later

Racks and structural steel often stay in place much longer than any one generation of LED fixtures. A well-planned grow glide rack gives you the flexibility to upgrade lights, dimming strategies, or even move into adjustable spectrum fixtures without rebuilding the room every time technology changes.

Because a grow glide rack increases how much canopy sits under each run of LEDs, it also supports investments in higher-efficacy fixtures and more precise dimming. Guides like HPS to LED Grow Lights Complete Guide and Mastering Dimming for Indoor Grow Lights are useful when planning those upgrades above a mobile-rack layout.

Design Tips When Using a Grow Glide Rack

Size HVAC and Dehumidification for Real Canopy Area

A grow glide rack adds canopy, and more canopy means more transpiration and heat per room. Cooling and dehumidification should be sized for the true production surface, not the original single-layer layout. This becomes even more important in multi-level rooms where several tiers share the same air volume. Most situations an air circulation system could help.

When you work through environmental capacity, it helps to keep VPD in mind. The troubleshooting notes in Experiencing Grow Issues? Check VPD translate well into higher-density mobile-rack rooms.

Treat Lights, Benches, and Racks as One System

Rooms perform best when the grow glide rack, LED fixtures, and tray dimensions are designed together. Ideally, each light bar is centered over a tray with consistent offsets from uprights, leaving enough space above for airflow and service access.

Use PPFD Mapping to Verify Each Bay

Once the room is built, PPFD mapping is the fastest way to check how each grow glide rack bay actually performs. Test at working mounting heights, on every level, and at different rack positions. That makes edge losses, beam shadows, and overlap problems visible before plants are in the way.

Conclusion

A well-planned grow glide rack does more than compress aisles. It reshapes how you think about canopy density, workflow, lighting layout, and future expansion. When it is integrated with efficient LEDs, optional under-canopy lighting, and a realistic environmental plan, mobile racking becomes a structural backbone for high-performance indoor production.

When you treat the grow glide rack, benches, and LED system as one platform instead of separate purchases, it becomes much easier to hit yield, quality, and operating-cost targets at the same time.