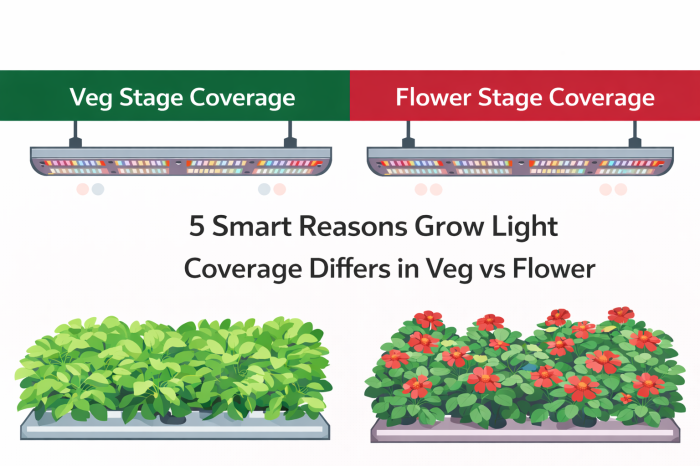

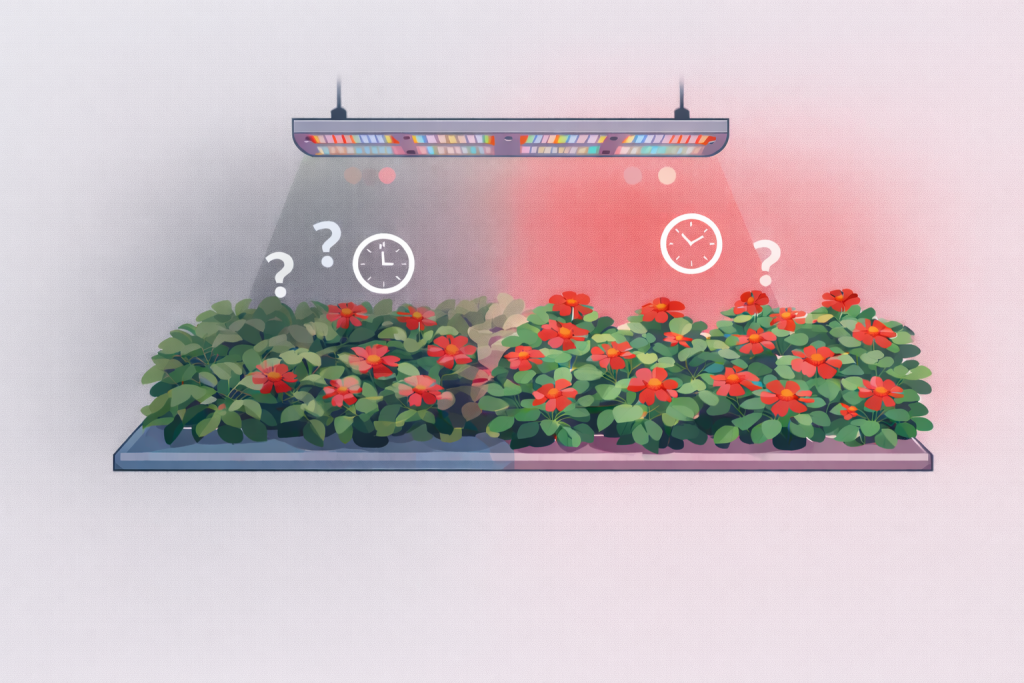

LED grow light coverage does not remain constant throughout a grow cycle. One of the most common design mistakes in indoor facilities is assuming that the same coverage area, fixture spacing, and light distribution strategy will work equally well during both the vegetative and flowering stages. In reality, coverage requirements change significantly as plants transition from veg to flower.

Understanding why grow lights for plants behave differently across stages—and how coverage must adapt—is essential for maintaining uniformity, avoiding wasted photons, and achieving predictable results at scale.

1. Canopy Density Changes the Way Light Is Intercepted

During the vegetative stage, canopy density is relatively low. Leaves are spaced farther apart, overall leaf area is smaller, and light penetrates through the canopy with minimal obstruction. Under these conditions, wide and forgiving coverage works well because photons are not immediately blocked.

As plants enter the flowering stage, canopy density increases rapidly. Leaf overlap becomes significant, upper growth layers intercept a larger percentage of incoming photons, and lower regions receive far less light. This change fundamentally alters how coverage behaves across the canopy.

What appeared to be sufficient coverage in veg can become uneven in flower because dense canopies amplify small distribution flaws and make edge losses more obvious.

2. PPFD Targets and Plant Sensitivity Are Different in Veg

Vegetative lighting strategies prioritize even coverage at moderate PPFD levels. Early-stage plants and young root systems are more sensitive to excess intensity, which is why running fixtures at full power in veg often leads to stress rather than better growth. Too much PPFD too early can cause leaf edge curl, light stress, or unnecessary stretching as plants try to escape localized hotspots.

In practice, growers typically have two primary tools to keep veg intensity in the right range without losing coverage:

- Increase mounting height: Raising fixtures softens intensity and widens effective coverage, which is why many manufacturers list a larger “veg coverage” than “flower coverage” for the same light.

- Reduce PPF or output: Dimming the fixture or running at a lower power setting keeps PPFD in a safe range for early stages without moving grow tables or restructuring the room. LED grow light from Grow Pros Solutions could be dimmed using controllers like Environment controller from Grow Pros Solutions.

As plants move into flower, PPFD targets rise and tolerance to intensity increases, but the acceptable margin for uneven coverage becomes smaller. Higher PPFD compresses the effective coverage area and makes distribution quality more important than raw brightness.

Modern facilities often add a third layer of control with adjustable spectrum grow lights. Multi-channel designs allow spectrum and PPF balance to be tuned by stage and cultivar, so coverage, plant response, and intensity can be aligned more closely without constantly reworking the physical layout.

3. Fixture Spacing Works Differently Between Veg and Flower

In veg rooms, fixtures can often be spaced wider because plants tolerate moderate variations in photon density. Coverage overlap is forgiving, and uniformity remains acceptable even when spacing is not tightly optimized.

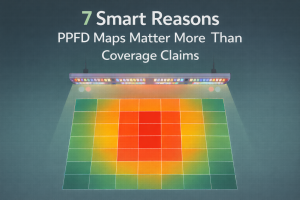

In flowering rooms, the same spacing frequently produces uneven results. High-intensity zones overlap excessively near the center while edges fall below target PPFD. What once felt like “full coverage” effectively shrinks as intensity rises and canopy density increases.

This is why many facilities discover that lights performing well in veg require tighter spacing, different hanging patterns, or a revised coverage strategy once flowering begins.

4. Uniformity Becomes a Limiting Factor During Flowering

Uniformity issues are often hidden during the vegetative stage. Lower intensity and open canopies mask uneven photon distribution. As flowering progresses, these same inconsistencies become obvious in structure, timing, and quality.

Uneven coverage in flower leads to inconsistent development across the canopy, staggered maturation, and unpredictable harvest windows. Some areas may finish early while others never quite reach the same level of development, increasing labor and reducing overall efficiency.

Grow light coverage strategies that prioritize overlap and smooth distribution become far more critical in flower than in veg. At this stage, uniformity is not a luxury metric—it is one of the main drivers of predictable results.

5. Lower Canopy Light Loss Changes Effective Coverage

In veg, most usable light reaches the full plant structure. In flower, dense upper growth intercepts a large percentage of photons, reducing effective grow light coverage below the canopy. Even when fixtures technically “cover” the same footprint, functional coverage shrinks because lower sites receive far less usable light.

This does not mean lights stop covering the area physically—it means grow light coverage must be understood in terms of usable light, not just geometry. As canopies fill in, many facilities respond by tightening fixture spacing, adjusting height, or introducing under canopy lights – a bar led grow light for under canopies or side of canopies – to restore lower vertical balance.

How to Plan Light Coverage Across Both Stages

Effective grow lights led design treats coverage as a dynamic variable rather than a fixed specification. Systems that perform well across the full grow cycle account for canopy density, PPFD targets, uniformity requirements, and vertical light loss from the very beginning of the design process.

Rather than relying on a single grow light coverage number, professional facilities plan lighting layouts that adapt from veg to flower while maintaining consistent distribution and predictable results. Grow light coverage is one part of a broader lights led grow strategy that also includes fixture selection, mounting height, spectrum control, and room layout. Grow Pros Solutions offers adjustable spectrum LED grow lights designed to more closely match different plant types and stages to their target PPF ranges within a stable grow light coverage plan, which is detailed in the main LED grow lights pillar content. For projects that also need to coordinate coverage with incentive structures, utility rebate support is available through partners such as Grow Lights Rebate.