$3,850.00

Take your Mushroom Cultivation to the next level with the Pure Station Compact! The work table surface is a high quality stainless steel meant for easy sterilization and corrosion resistance while each bench has been tested to meet Medical Equipment standards and requirements.

1x Mushroom Cultivation

1x Testing Lab

1x Tissue Culture

SKETCH MAP

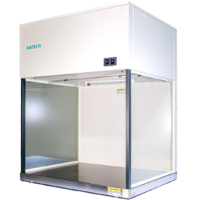

Expertly engineered for medium to large laboratories, Our PURE Station Pro Laminar Flow Hood accommodates a minimum of two technicians with ease. Crafted from premium stainless steel, it promises peerless durability and hassle-free sterilization. This state-of-the-art workstation boasts lab-grade UV-blocking safety glass, granting you unparalleled environmental control.

A laminar flow hood, often referred to as a clean bench, serves as a barrier against airborne contamination by delivering consistent HEPA-filtered airflow across the workspace. This technology finds applications in various fields, including non-hazardous sterile pharmaceutical compounding, microelectronics and optics assembly, microscopy, cell culture, and even mushroom cultivation.

Two common designs are vertical and horizontal laminar flow hoods, each with distinct advantages. Vertical laminar flow hoods save floor space and easily integrate into standard laboratory benches. They are well-suited for equipment or operations that require more vertical clearance. In contrast, horizontal laminar flow hoods provide airflow parallel to the work surface, reducing turbulence. This design allows sterile materials placed on the work surface to be positioned closer to the filter face, minimizing exposure to potential contaminants downstream.

Both types of laminar flow cabinets are available in explosion-proof configurations for use in hazardous areas where there is a risk of ignition due to flammable materials. Additionally, they can be configured as freestanding laminar flow hoods, complete with vibration-isolated tables for precision work.

| Cleanliness | ISO CLASS 5 |

| Air Velocity | ≥0.3 mis (59.1fpm) (adjustable) |

| Noise | ≤65 dB(A) |

| Illumination | ≥500 Lx |

| Power Supply | AC220 V, 1Φ, 50Hz |

| Consumption | 250w |

| Weight | 198 lbs |

| Work Dimensions | (48.8″ X 19.3″ X 21. 7″) |

| Overall Dimension | (52.0″ X 23.0″ X 37.4″) |

| Size & No. Of HEPA Filter | (47.6″ X 17. 7″ X 2.7″) |

| Light | LED 13.6w x 1 pc |

| UV Light | 8w x 1 pc |

| No. of Colony | ≤0.5cfu/dish • 0.5h |

There are no reviews yet.

Only logged in customers who have purchased this product may leave a review.